|

|

Post by Tight Git on Dec 8, 2009 17:14:25 GMT

|

|

|

|

Post by Miniböttcher on Dec 8, 2009 17:33:38 GMT

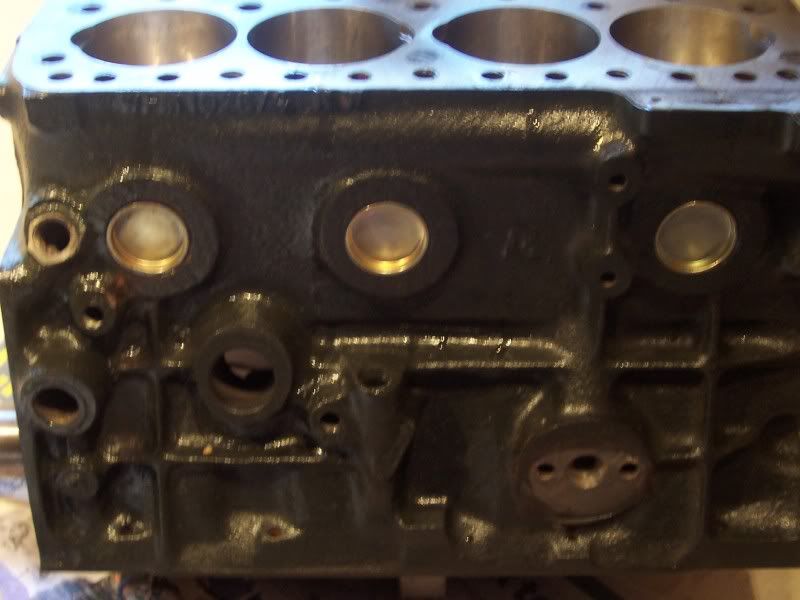

see your going the 998 route,with a 12g940 head as the pockets in the block, what spec are you going for ,

looking good, i built my block up a few weeks ago, just got the gearbox to go. i enjoy building them and making sure everything is right

|

|

|

|

Post by Bean Machine!!! on Dec 8, 2009 18:47:50 GMT

is that on a par 4 ;D ;D ;D got confused with all the holes another day another orifice     |

|

|

|

Post by Tight Git on Dec 8, 2009 19:40:48 GMT

Dean:

Oh yer, its all about the 998's..the spec is a little interesting, something a bit different,

it will be:

1096cc (not to be confused with 1098)

Lightened &Balanced where possible

12g940 head

etc. etc.

Should be a good little motor.

What's your spec then mate?

Alan:

hahah, yer looking back at those pics there an awful lot of holes..hows your mini doing?

|

|

|

|

Post by Miniböttcher on Dec 8, 2009 19:57:50 GMT

well, its going in my mk1

its a 998 cooper engine from a mk2

bored 0.040"with flat top race pistons,running at just under 9.5:1

crank ground 20/20

sw5 cam

swiftune duplex kit,( vernier timing gear, followers,oil pump)

lighterned flywheel and back plate, all balanced with the crank

centre main strap

12G295 head, polished,ported and chambered, larger valves, so around stage 3

twin 1. 1/4" with ram pipes

comp head studs

block has been had oil gallery drilled and tapped for grub screws

using a remote 4 sync box with a 3.1 , X pin diff and hardy spicers

should be nice onces its in and running but thats a long way off, still welding!!!!!!!!!

|

|

|

|

Post by Tight Git on Dec 8, 2009 20:00:42 GMT

haha,

That sounds a lovely engine, should have a nice amount of torque, perfect road car!!

|

|

|

|

Post by Tight Git on Dec 8, 2009 20:03:08 GMT

kinda wish i had gone for something more sensible like that in some ways.. but then the 80Bhp should make up for it!! ;D ;D

|

|

|

|

Post by Tight Git on Jan 4, 2010 1:03:44 GMT

|

|

|

|

Post by Miniböttcher on Jan 4, 2010 17:03:56 GMT

i am at about the same stage as you at the moment.

but if you cant turn the crank by hand, then its too tight,

i had the same problem, the person who took the engine apart mixed up the caps to the rods. so when it went together i also had to use the flywheel to turn it, and when i took it apart there was wear on the bearing shells,where it was pinching

, but once i found the problem and sorted it, it was perfect and could turn it by hand.

also using a engine stand makes life 100 X easier, plus you can torque up the bolt properly with out the engine spinning around on the bench, with out one you will find that it may not be all torque up the same.

i been there and done it, trust me it really helps to have one

but its looking really good, and going to be a nice little engine, i really enjoy building my engine and getting it right, just like most things

|

|

|

|

Post by Tight Git on Jan 4, 2010 18:01:17 GMT

Awesome mate,

problem solved, i had used the old bolts at the point the pictures were taken, today i unbolted all the caps and put my ARP bolts on and went through the torquing up procedure, she now turns over by hand, a little stiff where you would expect it but pretty good around TDC and BDC. She will get even smoother than that when i have got oil in her, instead of the assembly lube. I have however discovered i have made a very stupid mistake on the re-build all im going to say is that 2 of the mains caps have to come off.

Cheers for the advice mate really appreciate it, i was probably going to strip her again if she didnt free up after the torquing procedure, had a little something in the back of my mind which didn't feel right.

Got more problems now though, need to get hold of some threaded gallery plugs, my engineer tapped them without my knowledge, Anyone got any ideas?? also managed to loose my Camshaft woodruff key so going to have to another one of those, and im filing down that timing plate thing to make room for the countersunk screws to clear the Duplex belt, that takes an age...

Alastair

|

|

|

|

Post by Miniböttcher on Jan 4, 2010 21:10:48 GMT

thats good, i bolted mine up 3 times untill i was happy with it.

you be able to get another cam shaft key from another camshaft, thats not a problem

the bloke down at sussex engine builders in eastbourne uses the grub screws for the oil gallery ,and its were i got mine from,

but i would give him a call first, he only let me have them as i know him. he keeps a small stock as he uses them on his race engines

give you local builders a call, swiftune, bill richards, they use them and may sell you 2. or go back to the machine shop who did the work a get 2

i tried for ages to find them, nowhere does them as they are M14. for somw reason

i do know that a vauxhall corsa uses them on the gearbox clutch side, through vauxhall you get themm, 5 in a pack but it was around £18 ( 3-4 years ago), ouch

also i used locking tabs on the main bolts and a dot of lock tight on the bolts to make sure,

|

|

|

|

Post by Tight Git on Jan 4, 2010 23:34:11 GMT

ive found a bolt that fits, so im gonna cut it into two, and then hack saw an a cross into it, and put it in with a screwdriver!

|

|

|

|

Post by Tight Git on Feb 21, 2010 18:37:16 GMT

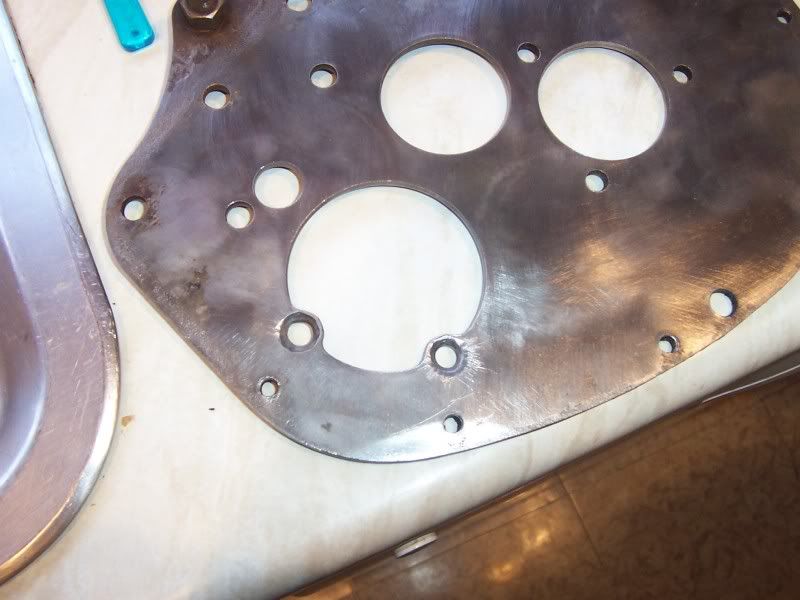

Well have a little update. Taken off my main bearings caps to correct a school boy error i made on the initial assembly! looked a the shell bearings whilst i was there, all is good!! however the assembly lube in my opinion is not going to provide enough lubrication for the initial turning over of the engine; so i mixed it with a little engine oil as well, and re assembled, she now turns over a lot smoother and I'm much happier! Also popped my Core plugs in:   Cleaned up my front plate:   And if you are looking for an easy way to put oil in places try this:  Just noticed that in the pictures my bores look in a bad way..they're not its just a trick of the light and the grease stuff ive been using to keep them rust free! Grease Monkey: I used Brake and Clutch cleaner on the shells. |

|

|

|

Post by Tight Git on Mar 7, 2010 22:56:37 GMT

took a trip home and did some more work on the engine so thought i would post up some news. Here is the problematic oil gallery plugs i cut down to size: and photos of them fitted.    And here is the progress: its not timed in but is done by dot to dot at the moment:   So getting it done slowly. |

|

|

|

Post by Tight Git on Mar 14, 2010 17:23:35 GMT

Well ended coming back from the big smoke for a second weekend running, so more engine work was done!! Right, i have now timed the cam in correctly It's timed in at 106 degrees, i wanted to time it in at 105, but when i got the 106 reading after not much work i decided that it would be just fine. Swifty recommends that it sits between 106 to 108 so if the chain stretches 2 degrees it will still be in limits! as a personal reminder I HAVE NOT TORQUED THE CAM SPROCKET NUT!!  Also i have installed the Oil pressure relief valve - using the Cooper S ball bearing system and a suitable spring with correct length and strength. I also installed the Dizzy blanking plug which took a little persuasion but got there in the end! also not pictured i installed the Fuel pump blanking plate with gasket! and the Kent High performance oil pump!  |

|